A Wide Range of Products

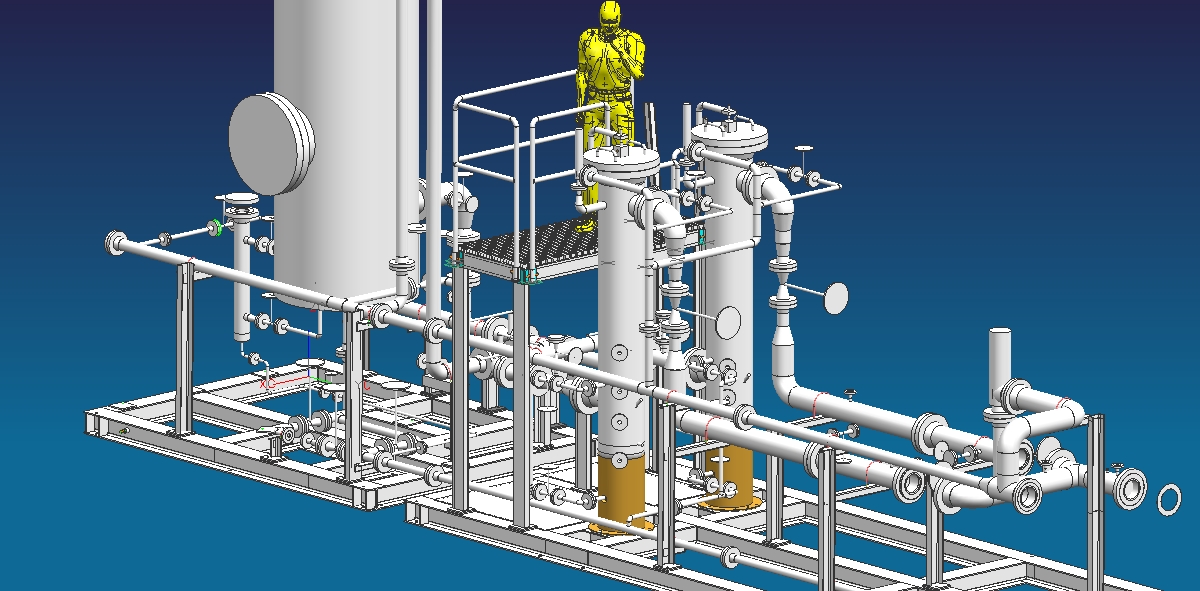

We have engineered several customized instrumentation components for the process automation. Analogic and digital sensors for measure temperature, pressure, flow and level as: multipoint thermocouples, flow elements - Venturi tube, flow nozzle and flow meter, multistage restriction orifice, metering system - control network, level gauge and PC gauging systems. We also engineer and install instrumentation packages, signal, special application cables, heating reaching systems. Our fire fighting systems branch is ready to design the best solution for detecting gas and fire extinguishing systems with a worldwide contraction skilled team. We have a wise experience in EPC of turbogas for electrical and compression stations. Electrical equipment, tanks boilers silos and heat exchangers, pipelines skids, measurement process control valves, SCADA and DCS Systems to complete our offer.

|

Thermoelements Our customized all type of thermocouples and thermoresistances cost effective, have fast response times, broad temperature ranges and can fit almost anywhere. We produce:

|

|

Flow elements Differential pressure primary elements are part of our portfolio:

|

|

|

|

I&E pakages The main purpose of Gas Treatment Packages is to filter, meter, heat and reduce the pressure, ensuring that clean and dry gas is delivered to the downstream user such as gas burners, gas-driven equipment (turbines, compressors), at the required pressure and temperature. Main packages for Gas Treatment are:

Key Features of Mesit systems are:

|

|

F&G Detection and fire extinguishing system Fire and gas fighting systems are tools for safeguarding process plants and production facilities that handle flammable and toxic materials. We assist our clients in the design, implementation and testing of these systems our service. include assistance in all phases of the fire and gas system lifecycle based on our unparalleled expertise, process knowledge and overall risk analysis capabilities including:

|

|

|

The Mesit@1 PLC provides single plant control for your most valuable asset, enabling comprehensive, connected plant automation. It offers a common hardware and software platform and common configuration for both safety and control. In addition, maintenance, diagnostics, spare parts, logistics, alarms, databases, and training are required for just one system simplifying operations. |

English

English  Arab

Arab  Russian

Russian  French

French  German

German  Chinese

Chinese

Administrative Office - Piazza Duca d’Aosta, 12 - 20124 – Milano +39.02.72022835 +39.02.72023798 fax -

Administrative Office - Piazza Duca d’Aosta, 12 - 20124 – Milano +39.02.72022835 +39.02.72023798 fax -